Aurora Voices with Randy Reibel

Meet our team | November 20, 2020 | 4 min. read

Our Aurora Voices series celebrates the people and teams whose unique experiences, backgrounds, and voices bring Aurora’s mission to life.

Meet Randy, Aurora’s VP of Lidar and the founder of Blackmore

Randy Reibel is a founder and entrepreneur at his core. He built and led Blackmore, the industry-leading lidar company acquired by Aurora last summer, and his team played a big role in the recent launch of Aurora’s next-generation trucks. As Aurora’s VP of Lidar, Randy’s team is responsible for FirstLight Lidar, the FMCW technology that enables trucks to see further than ever before, unlocking the ability to pursue autonomous trucking. When Randy’s not working, he can be found playing Pickleball or doing strength-training.

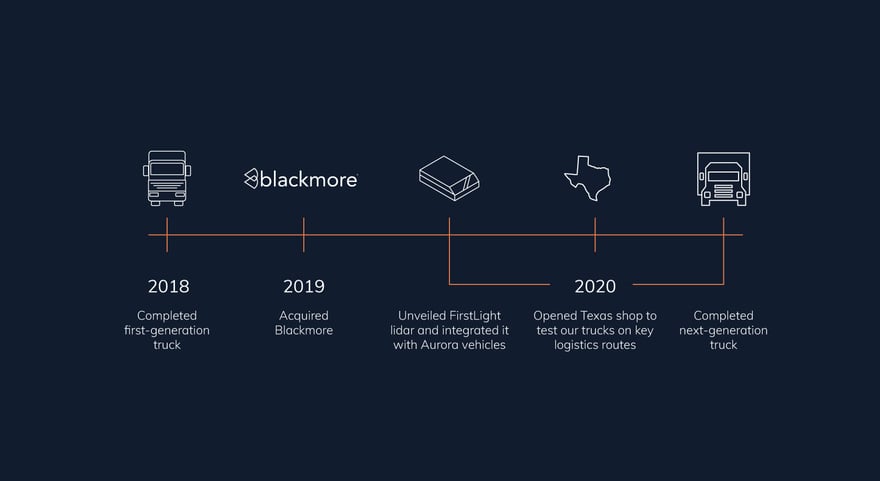

Here’s a timeline showing the deliberate path we’ve taken in building our autonomous trucks and the important role that acquiring Blackmore and its FMCW lidar has played.

What is your role at Aurora?

Aurora’s vehicles “see” the world around it using different sensors — cameras, radar, and lidar. As the VP of Lidar, I work across the organization to set the vision for our internally-developed lidar products: determining the appropriate requirements for our product roadmap and then ensuring the lidar team has the resources to make it happen.

What makes FMCW lidar such a game-changer?

Before I joined Aurora, I was the CEO at Blackmore, where we were developing FMCW lidar. FMCW lidar has three major benefits when compared to traditional lidar sensors. First, FMCW lidars are incredibly sensitive and that allows long-range sensing. Second, these sensors measure both range and velocity, allowing additional information to be collected at every single point in the pointcloud, which enhances perception. Finally, the sensors are not sensitive to interference, allowing them to operate directly in bright sunlight or when other lidars are on the road in close proximity. Given highway speeds, FMCW lidar’s longer range and precision perception are essential for self-driving trucking applications.

What is your proudest moment at Aurora?

Making the first-generation FirstLight Lidar and seeing that on our fleet. It brought folks together from across the company—perception, calibration, software, mechanical and electrical engineering, optical engineering, and production—and it was a true “win together” moment for Aurora.

Tell us about one of the coolest challenges you’re trying to solve.

Following the launch of FirstLight Lidar, we need to mass-manufacture these systems for our future commercial fleet needs. To do so, the engineering team is working to design photonic integrated circuits that effectively reproduce many parts into a single semiconductor chip that can be stamped out in large quantities at commercial foundries. This process is very similar to producing silicon chips. But while these types of processes have been matured by the telecom industry, there are significant differences when doing it in our industry. Our team has already made significant advancements in producing the world’s first mass-manufacturable FMCW lidars.

You were a founder and entrepreneur and then joined Aurora. Why did you and the team join Aurora?

One of the most important traits an entrepreneur can have is a flexible and open view of the world and what’s possible. It is through flexibility and openness that new ideas can be discovered and curated. As we thought about Blackmore’s core technology and path, we understood what we’d gain by joining forces with the Aurora team. Now we’re able to move faster working together and we’ve gained a diversity in skillsets and perspectives.

The early Blackmore team about two years prior to joining Aurora.

The Blackmore team in Bozeman, MT right after the team joined Aurora.

What was the process of integrating Blackmore? Can you talk about that experience, both from the tech perspective and what it meant for the team?

There were lots of questions from the team in the beginning and we were honest that there would be some change and uncertainty along the way. We had a team from Aurora on site for the first several weeks of the integration, which helped us understand Aurora’s values, policies, and what being an Aurora employee means. This helped our team assimilate at a faster pace than any other integration I’ve seen.

It was important that our team didn’t feel like a stand-alone business unit and we worked hard to quickly integrate both our technology and our team. For example, our production team expanded to not only build lidar, but to use our expertise to build Aurora’s computers and other hardware for Aurora’s self-driving trucks and Pacificas. Our analytics team became part of the broader software team. Other engineers joined the world-class Aurora simulation team to integrate product enhancements into the lidar simulation capabilities.

It was obvious that Aurora’s senior leaders cared deeply about our employees and their success within Aurora. The Bozeman office quickly became part of the Aurora family. There was some overhead in learning the new systems and structures, but ultimately, it meant our team could do even better work, and do it much faster.

When Aurora acquired Blackmore it opened up a new office in Bozeman, Montana. What’s Bozeman like?

Bozeman has a tremendous amount to offer in the engineering and technology world. It’s a university town with a high density of manufacturers of highly integrated optical assemblies. Bozeman also has a world-class quality of life, with excellent outdoor opportunities like skiing, hiking, and fishing. It’s a great balance of quality of life and high-tech professional opportunities. Everyone should come visit!

What Aurora value resonates most with you and why?

Set outrageous goals. I have always liked breaking new ground in research and development, but it’s not enough to make new things happen — they need to be practical and accessible. It’s never been enough for me to just prove something was possible. I have always wanted to make a difference by getting new technology into the hands of those who need it most.

What do you do when you’re not working?

I am working on becoming a strength-based athlete, which means changing my diet and adding in more strength and conditioning programs. I’ve always loved sports. I played tennis in college and now I am a Pickleball fanatic.

It continues to be a busy and exciting time at Aurora and we’re hiring for many positions across all of our offices. To find out more, visit our Careers page.

Delivering the benefits of self-driving technology safely, quickly, and broadly.